Don’t Let Bad Pallet Jack Wheels Slow Your Roll

by Enrique Hernandez, on October 30, 2025 at 12:37 PM

Clunk, clunk, clunk.

That's the sound of worn-out pallet jack wheels, and it's eroding your productivity. Bad wheels aren't just annoying. They're physically more demanding to use.

The flattened side creates more friction with the floor, making them challenging to push and putting more physical strain on your operators. Consequently, operators move more slowly and accomplish less. Worse, the added strain increases their risk of a workplace injury, triggering compensation claims and days away from work.

Choosing the right wheels for your pallet jacks solves all of this. The right materials hold up better, ensuring your team works as efficiently as possible.

Read on to learn more about what causes pallet jack wheel flats and what you can do about them.

Why Do Pallet Jacks Get Flats?

There are three primary causes of flat wheels on pallet jacks.

Heat

Many plastics soften when heated.

For plastics like the polyurethane in some pallet jack wheels, even the summer heat can be enough to deform them. Sitting stationary in a hot warehouse, the wheels soften enough to become malleable. Then, they form themselves to the floor, becoming flat on one side.

Sometimes, reheating the wheels and using the pallet jack is enough to restore the shape, but this is unreliable at best.

Pitting

Pitting occurs when soft wheels roll over rough, hard surfaces.

Think of it like a cheese grater. A wheel made of a softer material, such as polyurethane, rolls over a more rigid material, like asphalt, and the harder material carves away at the softer material. In a warehouse setting, this most often occurs when operating pallet jacks in environments with high levels of debris and outdoor spaces.

There are pros and cons to each wheel material, but selecting the proper hardness for your specific setting is crucial.

Shearing

Have you ever tried pushing a cart through a store with tight aisles?

You're at a home improvement store or a grocery store, trying to weave around the merchandise and other patrons. Yet, the turning radius on the cart keeps sending you into shelves, so you give the cart a yank sideways to get a little extra maneuvering room.

That lateral movement causes shearing.

Dragging wheels in a direction they can't roll puts a frictional force on the wheel material, causing it to scrape off a section and creating a flat spot. The same principle applies to your pallet jacks. Navigating narrow aisle warehouses with a pallet jack can be challenging. Many models don't turn on a dime. Sometimes, associates pull them sideways to gain those extra few inches they need to avoid a corner.

While understandable, this action ruins your wheels.

What Do You Do About Flat Pallet Jack Wheels?

Pallet jacks are a great alternative to forklifts, but the type of wheel you choose makes a significant difference.

Admittedly, shearing is a behavioral issue, and investing in a pallet jack with a tight turning radius is the most effective solution. However, the solution for heating and pitting is a question of wheel material. The most common material choices are polyurethane and nylon. The topic of pallet jack wheel materials warrants a thorough examination in its own right.

However, here’s an overview of the most important distinctions.

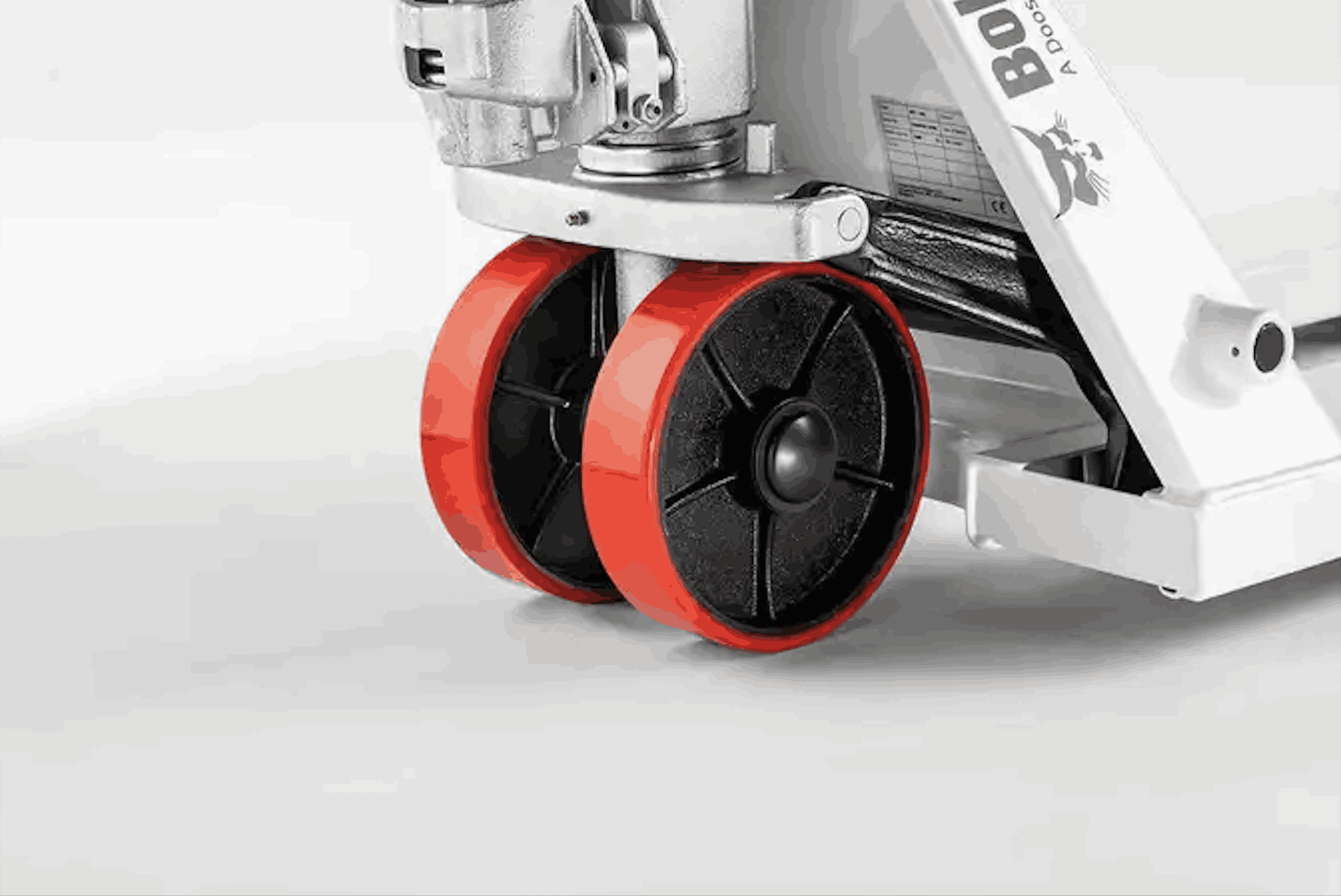

Polyurethane Pallet Jack Wheels

The benefits of polyurethane wheels are two-fold.

First, these wheels are quieter than nylon wheels. Quieter wheels are less bothersome to customers, making these wheels excellent for retail locations. Second, they are non-marking. In most cases, these wheels will not scrape or scuff your floor, keeping your facility looking cleaner and more professional.

However, polyurethane is softer than nylon.

Due to their softness, these wheels are not suitable for outdoor use or in environments with a lot of debris. Debris-heavy areas will pit these wheels, forcing you to replace them frequently. Additionally, polyurethane is more susceptible to heat than nylon.

A harder polyurethane may be more resistant to heat than other wheels of a similar material. However, the work environment is still worth considering when choosing replacement pallet jack wheels.

Need to get serious about cleaning your warehouse? Get this warehouse cleaning checklist and plan.

Ultimately, polyurethane wheels are often the best choice for indoor use in climate-controlled spaces, such as retail stores.

Nylon Pallet Jack Wheels

Nylon wheels are tougher than their polyurethane counterparts.

These wheels are designed to withstand cold, wet, and rough floors. They handle debris-filled containers and are resistant to chemicals. Consequently, nylon wheels are the recommended choice for outdoor use and unloading trailers.

That said, nylon has a couple of drawbacks.

These wheels are noisier than polyurethane and more likely to mark your floor. These issues might be inconsequential for some facilities. However, they should give customer-facing facilities pause as the noise can disrupt your clients and the marks may diminish your professional image in their eyes.

The bottom line is that nylon is better for harsh, rugged environments.

Experts in Pallet Jack Parts

The nuances between replacement pallet jack wheels can make selection challenging.

That's where we can help. Our experts make it their business to know all the little, overlooked differences between available parts. This refined technical knowledge enables us to help you select the ideal wheels to keep your pallet jacks rolling smoothly.

To learn more about pallet jack wheels and other pallet jack parts, contact us online or visit one of our locations.

Auburn 253-854-5438

Pasco 509-547-7413

Wenatchee 509-663-9009

Yakima 509-457-5137

Further Reading

Polyurethane or Nylon Pallet Jack Wheels: Which Do I Need?

Choosing Your Pallet Jack: Manual or Electric

Top 4 Alternatives to Forklifts