Polyurethane or Nylon Pallet Jack Wheels: Which Do I Need?

by Phil Hanford, on May 28, 2021 at 4:30 PM

So, you’re stuck on which wheels to go with for your hand pallet truck (HPT). It’s a bigger decision than you think. The good news? There are really only a couple of materials to choose between. Let’s break down the pros and cons of polyurethane vs. nylon pallet wheels below.

So, you’re stuck on which wheels to go with for your hand pallet truck (HPT). It’s a bigger decision than you think. The good news? There are really only a couple of materials to choose between. Let’s break down the pros and cons of polyurethane vs. nylon pallet wheels below.

Wheel Configuration

You’ll find both polyurethane and nylon pallet jack wheels on HPTs. With every truck, there are two small wheels — called load wheels - set into the forks. Meanwhile, the larger, swiveling steer wheels are located on the handle side. Depending on how you use your pallet truck, you’ll need to choose between these two materials.

Pros and Cons of Nylon Wheels

Nylon pallet wheels are tough. They are made to withstand harsh conditions like cold freezers, debris-filled containers, and rugged semi-truck trailers. However, they come with two drawbacks: they’re more likely to leave marks on the floor, and they’re louder than other wheels.

They do have specific benefits you may need. Nylon wheels are:

- Durable

- Puncture-resistant

- Chemical-resistant

- Ideal for rough, wet, or cold floors

Pros and Cons of Polyurethane Wheels

In general, polyurethane pallet jack wheels don’t leave marks or scratches on the floors. They’re also quieter compared to nylon wheels, making them ideal for retail workplaces. Unfortunately, making too many trips on rough pavement or onto a wet loading dock will damage these wheels and break them down.

Other considerations of polyurethane:

- Quieter compared to nylon wheels

- Better for your retail business

- Leave fewer scratches and marks on the floor

- Not ideal for rough floors or those with debris

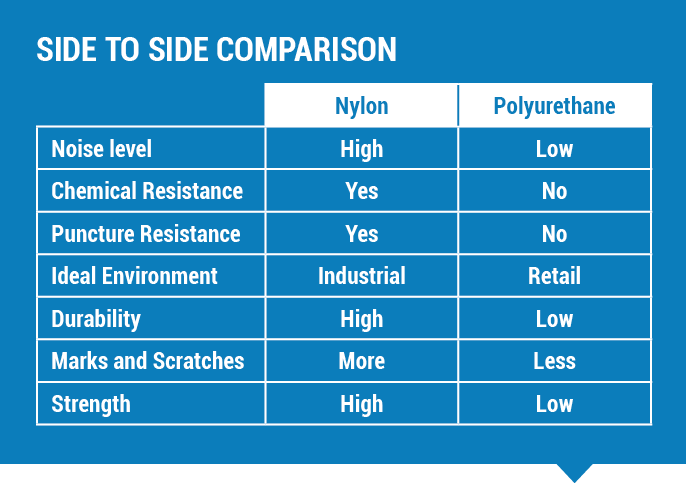

Side to Side Comparison

How to Choose Between Polyurethane and Nylon Pallet Jack Wheels

There are crucial differences when you choose between nylon and polyurethane wheels. Here are a few questions you can use to help you decide:

Where Will You Be Using Your HPT?

Do you use your pallet truck inside a retail environment, or do you mainly unload trailers? For those who have enough in their budget, the best thing to do is use two pallet jacks. You can use one that’s for your retail space only, with the other one for the distribution area.

Will You Mind Marks on the Floor?

Do you need to have clean floors at all times? If this is a big concern for you, then it's best to use polyurethane wheels. If you work in an industrial area, though, you’ll need heavy-duty, durable wheels, and nylon is the best choice for you.

Are Your Floors Usually Clean or Covered in Debris?

Lastly, you need to ask yourself if your floors are always free of debris. Your main concern with polyurethane wheels is that they won’t do well on rough surfaces. If you use your pallet truck primarily in distribution areas or the warehouse, you’re better off with nylon wheels. They can handle areas with debris much better.

If you need help choosing your pallet jack wheels, the material handling professionals at Mid-Columbia Forklift and MidCo Material Handling can help. Contact us here to get the conversation started and see what models we have in stock. You’ll get more details on which pallet jack replacement wheels would work best for you. You can also reach out directly to our dealerships by phone:

Auburn 253-854-5438

Pasco 509-547-7413

Wenatchee 509-663-9009

Yakima 509-457-5137